HEELS AND ACCESSORIES

RAPID PROTOTYPING

3D Printer, 3D Scanner ->

3D Printer, 3D Scanner ->

Starting from an idea, our designer team is ready to satisfy any type of request from our partners. First of all, we design the prototype with the best CAD / CAM and 3D scanner software, and then created with the latest generation of 3D printers, which allow assembly tests, coating, and use for fashion shows.

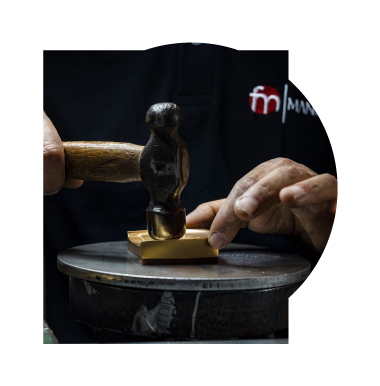

MOULD DEPARTMENT

specialized for making moulds ->

specialized for making moulds ->

Flexibility and dynamism, with our production workshop, we considerably reduce mold making times. From the design of the mold to the realization we manage all the industrialization phases with the machining centers, lathes and CNC.

15 INJECTION MACHINES

production capacity of 15 thousand pairs per day ->

production capacity of 15 thousand pairs per day ->

We use different molding materials such as ABS, polystyrene, resins, acetate. Products injected in leather and wood, TPU bottoms and accessories of all kinds.

MAKINGS AND FINISHES

leather, lacquering, galvanic, demoulding, plexiglass and jewel heels ->

leather, lacquering, galvanic, demoulding, plexiglass and jewel heels ->

We guarantee every kind of finishing on heels, wedges, plateau, accessories and wooden clogs and shoetree.

SHAPE